Tank Foundations

Subgrade and Foundation Considerations

In all ModuTank Inc. products, there is no requirement to use a specific base material over another, nor is there a formal earthwork design minimum that must be followed. In almost all cases, as these are not welded tanks, our vessels perform well on nearly any level site, and placement directly over native soil is typically acceptable. Fill material is generally not required unless the existing surface consists of large or uneven stones, poorly crushed gravel, or similar conditions. In those cases, a layer of sand may be used to fill voids and provide a smooth, uniform surface for our geotextile underlay and membrane liners.

Compacted earth to approximately 95 percent Proctor (or equivalent) is considered fully adequate, and while a full concrete pad is not required, if desired, our tanks can just as easily be anchored using standard expansion bolts.

General Subgrade Characteristics, (compacted earth tank pads)

For proper installation on earthen sites, the subgrade should meet the following general conditions:

- Stable and capable of supporting the imposed loads

- Properly compacted to prevent differential settlement

- Free of large stones, brush, debris, or objects that could puncture the liner

- As flat as reasonably possible

- As level as reasonably possible

- Low permeability

- Material homogeneity and uniformity

- Use inert, non-corrosive, and stable bedding material

- Maintain appropriate tank perimeter clearance on at least (1) side

- Graded to slope away from the tank to prevent water from pooling against wall panels during heavy rainfall

Free-Standing Installations and Flexibility

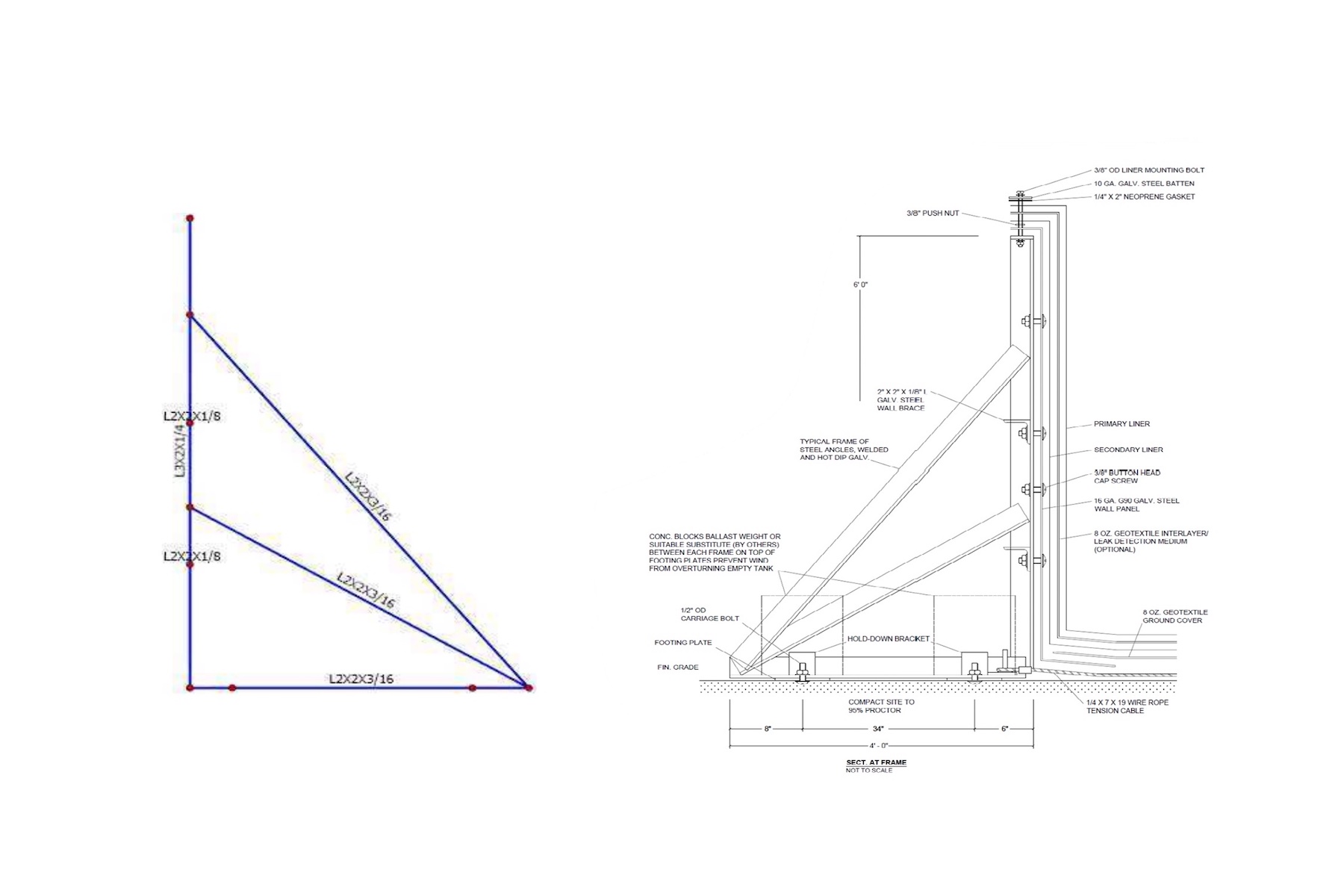

When tanks are installed in a free-standing configuration, meaning they are not mechanically anchored to the ground, ballast weights are placed on the various “footing plates” our tanks are shipped with, to resist wind and potential seismic forces. Minor out-of-plumb conditions in frames or wall panels do not pose a structural concern, as again, these are not welded tanks. These tanks are intentionally designed to accommodate imperfect site conditions through inherent flexibility and the internal network of tension cables located beneath the liner(s).

Engineering Review and Tolerances

While ModuTank does not publish formal earthwork tolerances or slope limits, our consulting professional engineers can provide stamped, site-specific calculations for our tank structures, wind loading, and seismic ballast requirements, in all 50-states and a number of countries worldwide. These calculations can be tailored to the exact installation location. Historically, tanks have been installed on sites with measurable slopes—sometimes several feet of elevation change over 100 feet of length. In these cases, the primary impact was a reduction in usable capacity rather than a structural limitation.

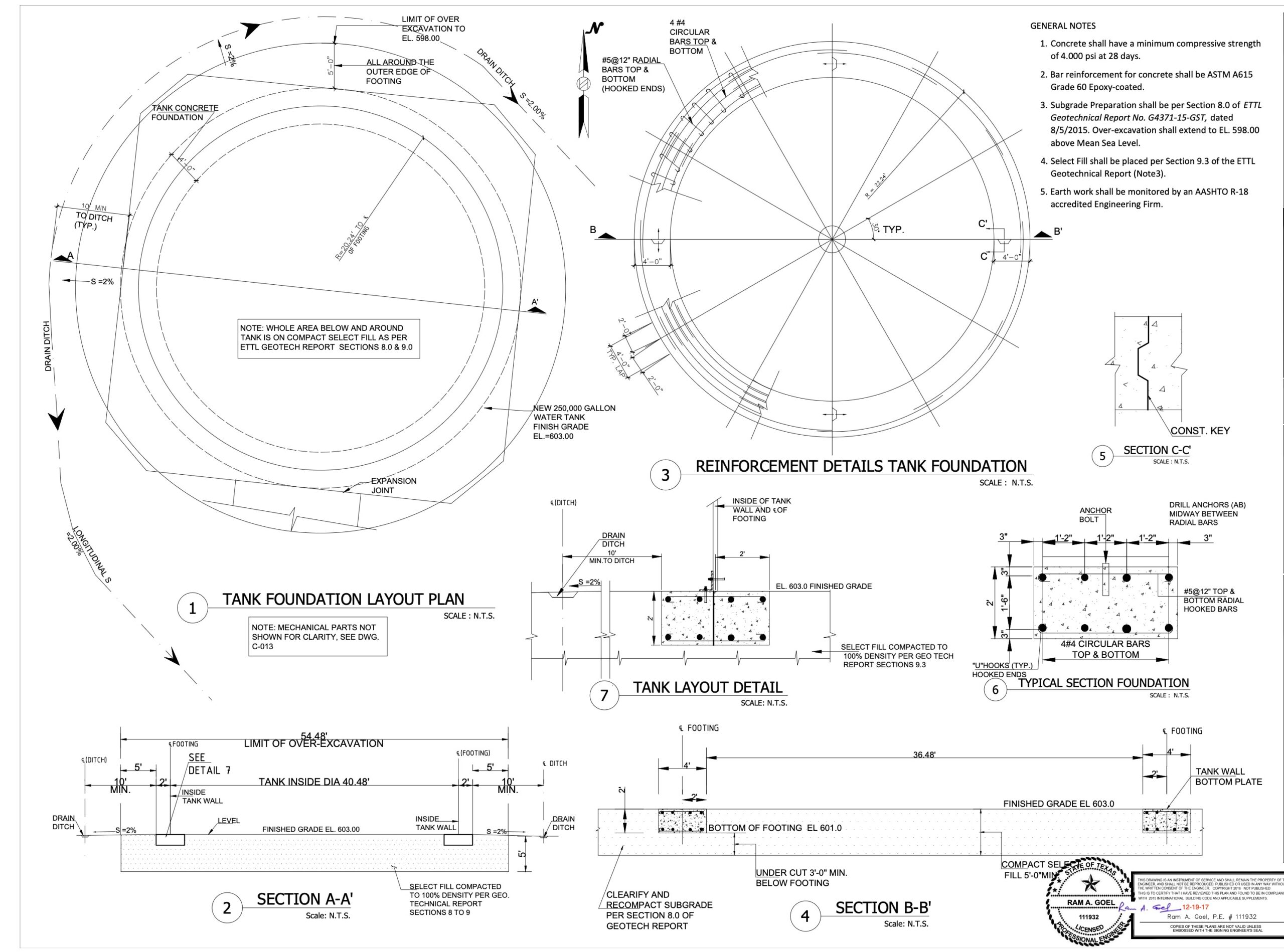

Concrete Foundation Options

For each ModuTank model, although a full concrete pad is never required, clients may elect to use existing pads, or pour formal foundations. Round tank installations can utilize a simple 4-foot-diameter concrete ring wall, with compacted earth remaining at center. The same idea may be followed on our square and rectangular tanks, where a perimeter concrete apron can support the structural support frames, and compacted earth fills in the remaining space. This approach can significantly reduce construction costs, when a concrete slab is not already present. Please see examples of these foundation types, in the following photos and drawings: